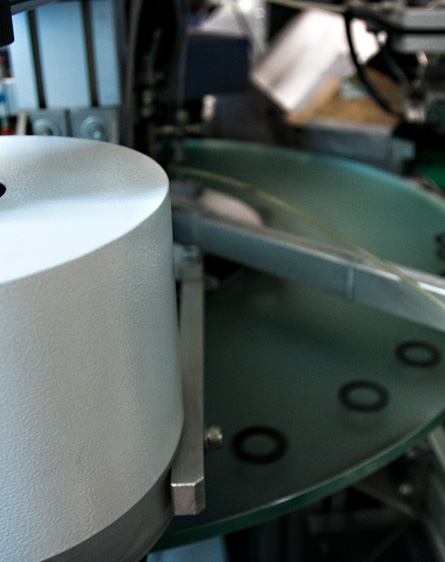

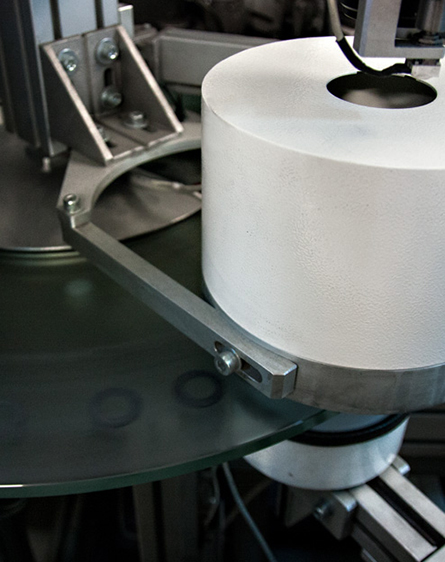

PRODUCTION PROCESS

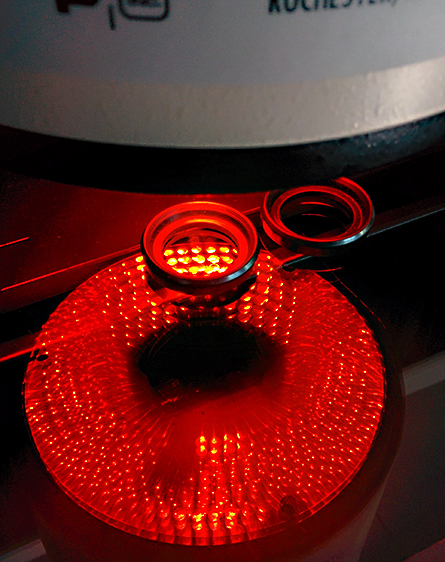

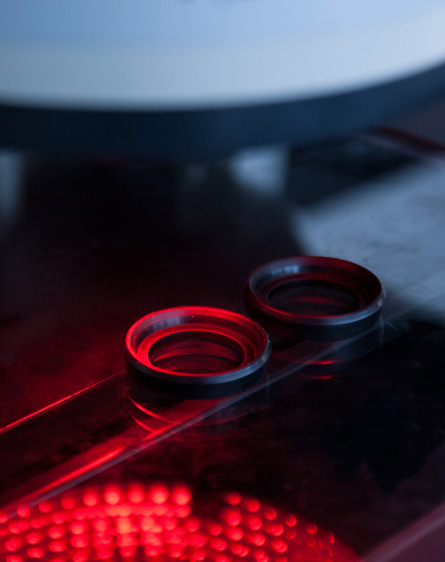

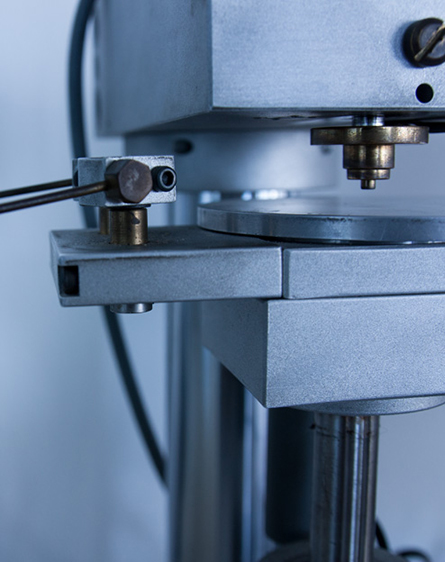

ACCEPTANCE OF RAW MATERIALS

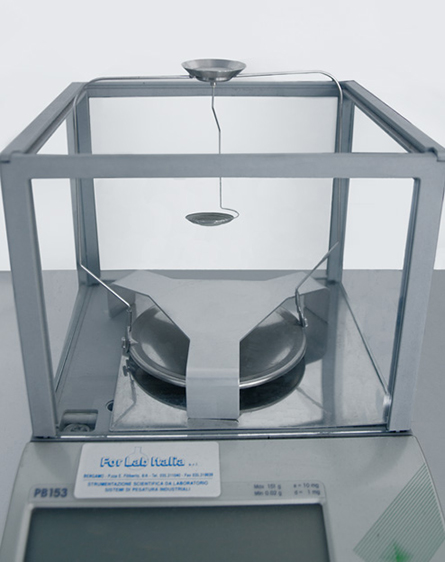

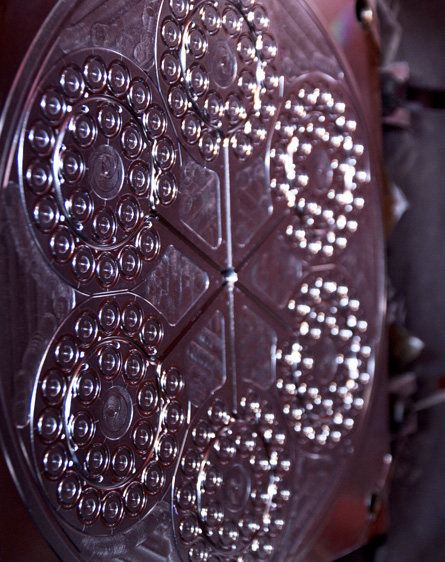

In order to ensure high quality products it is really important to be sure of the raw materials quality. For this reason, our suppliers are constantly monitored by our Quality Control Office. Besides, we always check the raw materials to ensure their compliance with the required specifications. Our laboratory verifies the raw materials hardness, specific gravity, and whenever necessary, it also checks the compression set, resistance to oils, etc.